Pratt & Whitney’s Industry 4.0 Strategy Driving Operations Modernization

Lean, connected, automated initiatives resulting in increased efficiency, productivity

Pratt & Whitney is modernizing and transforming its Operations business with Industry 4.0 technologies in the pursuit of unbeatable manufacturing and assembly excellence. The company is leveraging digital communication technologies like the Intranet of things (IoT) and connected devices, along with advanced manufacturing technologies including automation, robotics, virtual reality, and closed-door machining, to create a fully integrated manufacturing environment. These initiatives drive immense amounts of data that can be immediately converted to useable information.

“We’re driving higher levels of process capability, optimized with lean principles, automated where appropriate, and in a connected environment that collects data, runs analytics, and provides information to operators and leaders in real-time,” said Praba Baptist, vice president, Operational Excellence, Pratt & Whitney. “This digital ecosystem has allowed us to continuously improve, sharing best practices for adoption across our manufacturing footprint. This is the next evolution in lean manufacturing and one way we are going beyond for our employees, customers, and shareholders.”

CORE™: A Framework for How Pratt & Whitney Does Business

A key driver of Pratt & Whitney’s transformation is the Raytheon Technologies CORE Operating System. CORE, which stands for Customer Oriented Results and Excellence, provides a common language, toolset, and methodology for delivering on customer commitments. It was designed with Industry 4.0 capabilities built in and is a framework for how Pratt & Whitney does business.

Investments supporting CORE and Pratt & Whitney’s Operational Excellence strategy — including connected factory, automation, and enhanced process control — have improved the overall effectiveness of its manufacturing footprint with enhanced employee experience, which in turn has resulted in reduced variation and waste in the production of the company’s products.

Connecting the Factory by 2024

Pratt & Whitney’s connected factory initiative enables integrated, real-time demand planning to ensure alignment to meet customer demand. Automated workflows, real-time materials and data tracking, scheduling, and energy optimization are just a few examples of how a connected factory can improve efficiency while reducing time and waste.

This initiative has increased productivity and asset turnover, and the ability to have the right quantity of the right part at the right place at the right time.

The company has connected over 40% of total machines to date and plans to connect 100% of original equipment manufacturer (OEM) machines and 75% of Aftermarket machines enterprise-wide by 2024. All new machines procured during and after that time will automatically be added to the connected system.

Automating for Superior Safety, Quality, Productivity & Cost

The introduction of highly automated solutions across Pratt & Whitney’s manufacturing footprint is targeted at improving safety, quality, productivity, and cost.

The company is focused on automating repetitive motion situations like torquing and directly loading and unloading heat treat operations. The efforts to use automation have improved quality by controlling the process, increasing productivity and machine utilization.

Pratt & Whitney is incorporating automation to enhance highly manual areas benefitting process control, while digitally harmonizing the “4Ms of manufacturing”— i.e., material, methods, machines, and man.

By incorporating these solutions, it creates a standard method that is scalable and opens a new level of speed and efficiency in delivering to the needs of Pratt & Whitney’s customers.

About Pratt & Whitney

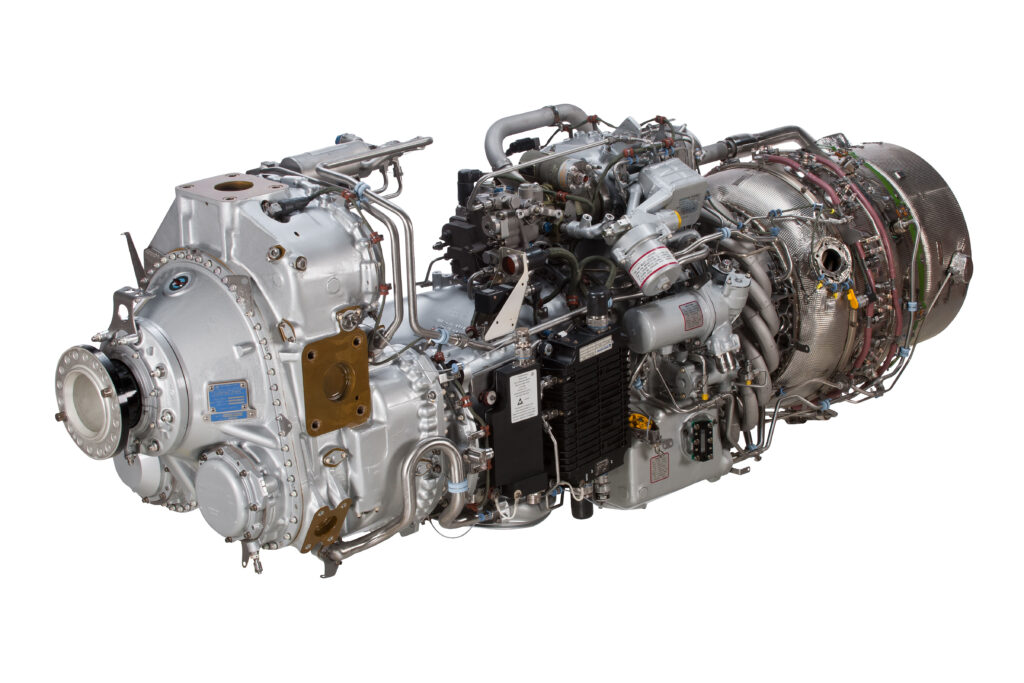

Pratt & Whitney is a world leader in the design, manufacture and service of aircraft and helicopter engines, and auxiliary power units. To learn more visit www.prattwhitney.com.