Flying Fuel Cell: MTU Aero Engines develops aviation fuel cell technology

- Cooperation with DLR: Maiden flight planned for mid-decade

- Market launch in short-haul applications planned for 2035

Aviation propulsion systems are a major factor in achieving zero emissions in the skies. As part of its Clean Air Engine (Claire) technology agenda, MTU Aero Engines is working on various concepts for all thrust and power ratings to achieve the aviation industry’s big goal. The company is focusing its efforts on the evolution of the gas turbine on the basis of the Geared Turbofan and on revolutionary propulsion concepts. “Among other things, we are forging ahead with the full electrification of the powertrain,” explains MTU COO Lars Wagner. “We’ve identified converting liquid hydrogen into electricity using a fuel cell as the area with the greatest potential for achieving this.”

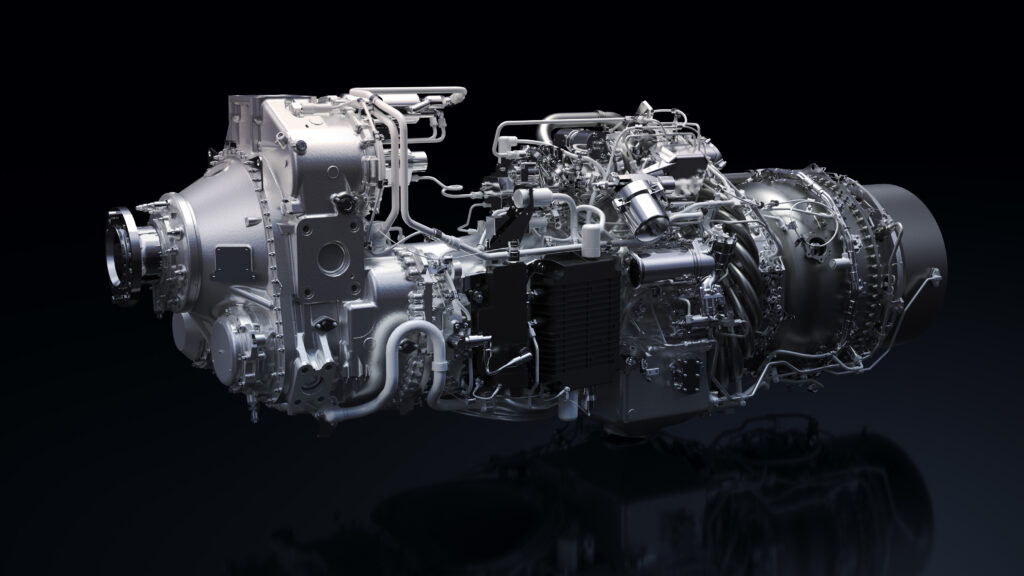

MTU’s revolutionary concept is called the Flying Fuel Cell (FFC). A team of about 70 experts – and growing – is currently working on the FFC in Munich. The principle behind it is that a fuel cell converts liquid hydrogen into electrical energy. This means a high-efficiency electric motor drives the propeller. There are various advantages to this approach. First, fuel cells are highly efficient. Beyond that, they do not emit CO2, nitrogen oxides (NOx), or particulates; the only emissions are of water. “The FFC reduces the impact on the climate by as much as 95 percent, so it’s practically zero,” explains Dr. Stefan Weber, Senior Vice President Engineering and Technology.

Plans call for the FFC to be used at first on shorter commuter and regional flights. Weber continues: “We’re aiming to launch on the market in 2035 there.” With improved efficiency, the Flying Fuel Cell will then be used in short- and medium-haul flights as well starting in 2050, further reducing the climate impact of commercial aviation.

Cooperation with DLR

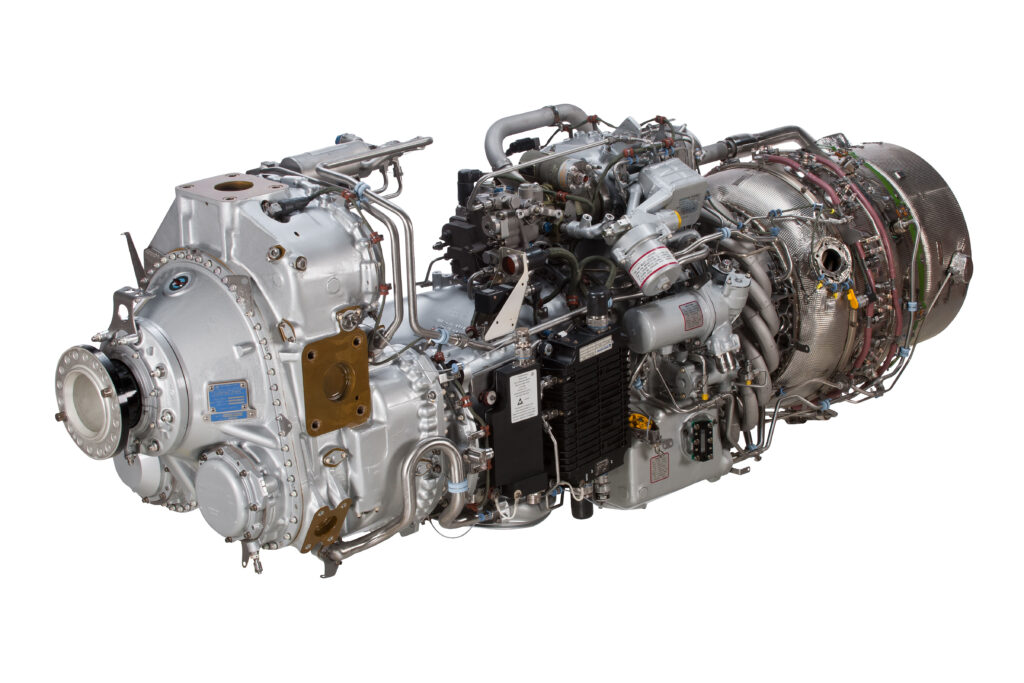

Work to develop the FFC technology is proceeding in cooperation with the German Aerospace Center (DLR). A Do228 is being used as a technology platform and flight demonstrator. The goal is to replace one of the two conventional gas turbine propulsion systems with a 600 kW electric powertrain with energy supplied by a hydrogen-powered fuel cell and test the new configuration. The partners aim to launch the flying lab in the middle of this decade. Extensive ground tests and advance testing will take place before then.

“MTU’s job is to develop the entire hydrogen-powered fuel cell powertrain, including the liquid hydrogen fuel system and controls,” explains Barnaby Law, MTU’s Chief Engineer Flying Fuel Cell. The Do228 research project is being headed by the DLR, which is providing the research aircraft and conducting the flight experiments. The research institution is also responsible for integrating the powertrain into the aircraft.

At the same time that this work is under way, MTU is also cooperating with the European Union Aviation Safety Agency (EASA) and working on approval requirements. Weber adds, “We have embarked on an innovation partnership where we are working together to study possible options for future certification of a flying fuel cell, since everyone involved is in uncharted territory here.” New standards, approval specifications, and documentation procedures will have to be defined in order for flying fuel cells to operate safely as an innovative propulsion concept.

COO Wagner sums up: “For an engine manufacturer like MTU, developing an airworthy fuel cell is a big opportunity, since the experience and data we gain in the process, including in the areas of control and qualification under aviation law, will be crucial to the further product development process.”

About MTU Aero Engines

MTU Aero Engines AG is Germany’s leading engine manufacturer. The company is a technological leader in low-pressure turbines, high-pressure compressors, turbine center frames as well as manufacturing processes and repair techniques. In the commercial OEM business, the company plays a key role in the development, manufacturing and marketing of high-tech components together with international partners. Some 30 percent of today’s active aircraft in service worldwide have MTU components on board. In the commercial maintenance sector, the company ranks among the top three service providers for commercial aircraft engines and industrial gas turbines. The activities are combined under the roof of MTU Maintenance. In the military arena, MTU Aero Engines is Germany’s industrial lead company for practically all engines operated by the country’s military. MTU operates a network of locations around the globe; Munich is home to its corporate headquarters. In fiscal 2021, the company had a workforce of over 10,000 employees and posted consolidated sales of almost 4.2 billion euros.

Your contact:

Martina Vollmuth

Press Officer Technology

Tel.: +49 89 14 89 53 33

Cell phone: +49 176 1001 7133

E-mail: martina.vollmuth@mtu.de

For the full collection of press releases and photos, go to http://www.mtu.de